The 7th China (Chengdu) International Additive Manufacturing Expo, 3D Printing Conference was successfully held——Focused on 3D Printing, Smart Manufacturing

From December 27 to 29, 2024, the 7th China (Chengdu) International 3D Printing Conference, a premier industry event focusing on the forefront of additive manufacturing, was successfully held at Chengdu Aviation Industrial Park, Chengdu Xindu High-tech Industrial Park. The three-day conference was carefully guided by the Chinese Society of Mechanical Engineering and the China Machinery Manufacturing Technology Association, and jointly sponsored by the National Additive Manufacturing Innovation Center and Xi’an Jiaotong University.

At the opening ceremony, industry leaders, including academician Lu Bingheng of the Chinese Academy of Engineering, leaders of relevant departments in Sichuan Province and Chengdu, representatives of upstream and downstream enterprises of the additive manufacturing industry chain, and expert representatives from scientific research institutions and universities, gathered to celebrate this milestone event.

With the theme of “Additive Manufacturing drives manufacturing innovation and 3D printing enters the Industrial Park”, the three-day conference closely focused on the development pulse of the additive manufacturing industry and gathers industry resources in an all-round way. The conference innovatively adopted the “1+6+N” mode, a high-level main meeting with six professional forums, accurately focusing on finance, energy and power, aerospace, education innovation and development, biomedical, automotive and rail transit equipment manufacturing and other frontier fields, while carefully setting up international academic conferences, technological achievements display, innovation and entrepreneurship competition and other diversified activities. In addition, the conference held the unveiling ceremony of the Additive manufacturing precision Medical Innovation Alliance at the same time, issued the “Chengdu Declaration” of additive manufacturing industrialization, the first new model of exhibition competition integration, seamless connection of meetings, parks and exhibitions, and presented a high-specification, authoritative and professional exchange and cooperation banquet for the additive manufacturing industry.

During the meeting, Mr. Michael Digkas, founder of China West Connector, as a foreign representative, held in-depth talks with major enterprises to explore technical cooperation and investment opportunities, building a new bridge for innovation exchanges between China and the west.

Mr. Michael Digkas mainly visited the following seven companies, including Haileer Group, Suzhou Zhongrui Zhichuang 3D Technology Co., LTD., Guangzhou CNC Equipment Co., LTD., National Additive Manufacturing Innovation Center, Sichuan Jinhua Aviation Technology Co., LTD., Shenzhen Adventure Technology Co., LTD., and Weinan Lingzhi 3D Technology Co., LTD.

Promote Technical Cooperation and Cross-border Exchanges

Weinan Lingzhi 3D Technology Co., LTD

Weinan Lingzhi 3D Technology Co., Ltd. was founded in 2016, focusing on the field of 3D human digital technology, which is a set of 3D human digital equipment research and development, technical support, data service in one of the high-tech enterprises.

As a frontier explorer of 3D digital technology, since its establishment, Linzhi 3D has fully integrated the upstream and downstream industry chain by relying on its own intellectual property algorithm and many years of 3D anthropometry technology advantages, and launched a series of 3D digital technology equipment including 3D body scanning system, intelligent face 3D scanning system, foot 3D scanning system, etc. Provide one-stop body data service solutions for customers in the fields of medical cosmetology, clothing customization, footwear customization, 3D printing, education and training, and digital display.

During his visit to Weinan Lingzhi 3D Technology Co., LTD., Mr. Michael Digkas gained detailed insights into the company’s groundbreaking advancements in 3D scanning and artificial intelligence (AI). The company has developed state-of-the-art machines equipped with AI software that not only simulate post-operative results for plastic surgery procedures but also analyze and identify areas of the human body that can be enhanced or improved. Mr. Digkas and company representatives discussed opportunities for international cooperation to introduce these cutting-edge technologies to the global plastic surgery industry, revolutionizing pre-surgical planning and patient consultations.

National Additive Manufacturing Innovation Center

Subsequently, Mr. Michael Digkas came to the National Additive Manufacturing Innovation Center to learn more about the latest application results of 3D printing technology, and also took a photo in front of a 3D printed car model. Mr. Michael Digkas focused on the printing of artificial aggregates and high-precision components.

The National Additive Manufacturing Innovation Center is the only national innovation center in the field of additive that has been planned and constructed by the State for the implementation of “Made in China 2025”. Guided by national strategic goals and manufacturing innovation and development, the center aims at cutting-edge common key technologies such as major equipment, important materials, key processes, core software, and core components, as well as innovative technologies, transformation technologies, and incubation technologies, and builds a complete innovation chain and industrial chain through multidisciplinary innovation and collaborative innovation of “government-industry-university-research and gold-use”. Drive the transformation and upgrading of the entire manufacturing industry and serve the strategy of China’s manufacturing power.

The National Additive Manufacturing Innovation Center has a core research and development team with 2 academicians of the Chinese Academy of Engineering, 5 distinguished professors, 2 experts of the Shaanxi Hundred People Plan as technical leaders, senior engineers and engineers with doctoral degrees as technical backbone, and master’s and professional technical personnel as the main implementation body. There are more than 230 employees, more than 80% of the R & D personnel, more than 80% of the master’s degree or above. It has won the honorary title of “Shaanxi Sanqin Scholars Innovation Team”.

In-depth Communication, Expand the Industry Vision

Suzhou Zhongrui Zhichuang 3D Technology Co., LTD

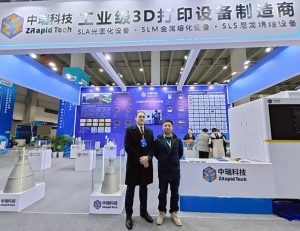

Mr. Michael Digkas discussed the application of 3D printing technology in the aerospace and automotive industry with representatives of Suzhou Zhongrui Zhichuang 3D Technology Co., LTD.

ZRapid Tech is a national high-tech enterprise specializing in industrial 3D printing equipment, 3D printing software, 3D printing materials research and development, production, sales and technical services as one of the leading additive manufacturing technology solutions provider in China.

The company has 7500 square meters of comprehensive office center, research and development center and manufacturing center. The company was founded by Dr. Zhou Hongzhi and a doctoral team with advanced work experience at home and abroad. The core technical staff has 18 years of 3D printing research and work experience, and has a full set of independently developed 3D printing data processing software and 3D printing equipment control system. A full range of industrial 3D printer product chains with fully independent intellectual property rights: SLA light curing 3D printer, SLM metal 3D printer, SLS nylon 3D printer, AMC ceramic 3D printer.

Printing materials cover resin, metal, nylon, ceramic, coated sand and other types. Zhongrui Technology is now the support unit of Jiangsu Rapid Manufacturing 3D Printing Engineering Technology Research Center, based on the forefront of international additive manufacturing technology. To promote the industrialization of additive manufacturing in China with the guidance of market demand at home and abroad.

Sichuan Jinhua Aviation Technology Co., LTD

At the booth of Sichuan Jinhua Aviation Technology Co., LTD., Mr. Michael Digkas learned more about the technical strength of the company in engines and UAV manufacturing. Mr. Michael Digkas said that the possible cooperation between Chinese enterprises and the west will help promote the diversification of technology applications and the internationalization of the industrial chain.

Guangzhou CNC equipment Co., LTD

In the field of smart manufacturing, Mr. Michael Digkas communicated with Guangzhou CNC Equipment Co., Ltd. Technology Co., Ltd. to understand the application advantages of smart equipment and innovative technologies. Mr. Michael Digkas held a practical dialogue with the head of the Chinese company on technology export, equipment supply and related legal safeguards. He stressed that the European market has a growing demand for smart manufacturing solutions.

Guangzhou CNC Equipment Co., Ltd. was established in 1991 and transformed into a private enterprise in 2000. After 30 years of hard work and efforts, the company has developed from a collective ownership enterprise of more than 20 people into a high-tech enterprise integrating science, education, industry and trade, and is known as “the numerical control industry base in South China”.

The main business includes: GSK machine tool control systems, AC servo drives and servo motors, spindle servo drives and spindle motors; GSK series industrial robots; GSKAEz series all-electric precision injection molding machine; CNC machine tool sales and CNC machine tool transformation; Highly skilled personnel training.

Guangzhou CNC is one of the first batch of high-tech enterprises, key software enterprises in the national planning layout, national innovative pilot enterprises, China’s top 100 software business revenue enterprises, the rotating chairman unit of China Machine Tool Industry Association, won the second prize of National Science Progress Award three times, and has a national enterprise technology center and postdoctoral research workstation. It has carried out technical cooperation with more than 50 famous domestic universities and research institutes, and set up joint research centers/laboratories with 8 universities: Harbin Institute of Technology, Nankai University, South China University of Technology, Shanghai Jiaotong University, Guangdong University of Technology, Tianjin University, Beijing University of Aeronautics and Astronautics, Xi ‘an Jiaotong University.

Based on the development situation of the equipment manufacturing industry in the domestic market, the company has extended the field of numerical control technology, created new economic growth points, developed and promoted the application of industrial robots, and achieved breakthrough results in the application and promotion of industrial robots. At the same time, the company relies on the leading advantage in the field of numerical control, extends the business field, and actively carries out the research and development and industrialization of precision all-electric injection molding machine.

Guangzhou CNC has set up a large-scale, professional R & D team, positioning to engage in CNC machine tool technology, industrial robot technology and other research. In addition, with the help of the research and development mode combining production, university and research, through the development of technology commissioning and the establishment of joint research and development centers, a number of research professors, master’s students, doctoral students and other researchers have been introduced to participate in the development of core technologies, and the organic integration of technical talent resources has been realized.

Guangzhou CNC R & D strength is growing, the establishment of a sound R & D management system, technological innovation mechanism construction, with enterprise R & D center and national and local levels of joint construction of the technology center. Actively advocate and practice the mode of industry-university-research cooperation, strengthen the construction of enterprise innovation infrastructure, and build a complete enterprise technological innovation system. With the continuous consolidation and promotion of the company’s position in the industry, the company’s talent gathering advantage will be more prominent, providing a solid R & D talent guarantee for the successful development of scientific research projects.

Shenzhen Adventure Technology Co., LTD

Shenzhen Adventure Technology Co., LTD., founded in 2015, is a technology company engaged in the development of ceramic 3D printing technology, ceramic 3D printing equipment and ceramic 3D printing materials. The core team members of the company come from Tsinghua University, Norwegian University of Science and Technology and other famous universities, with professors, postdoctoral and doctoral degrees, and their research and development capabilities constitute the core competitiveness of the company. The company takes “self-improvement and innovation for the nation, creating value for the country, taking responsibility for the society” as the company’s vision, adhering to the development concept of “technological innovation, integrity first”, and is committed to providing customers with comprehensive and perfect ceramic 3D printing solutions.

Deepen Cooperation and Promote Innovative Development

Finally, Mr. Michael Digkas spoke with the management of the Haileer Group and highly appreciated its advanced solid-state battery manufacturing and environmental protection technology. The transnational application of innovative technology in agriculture, energy and industry was discussed, and the intention of technical cooperation was initially reached.

Haileer Group

Founded in 1995, Haileer Group is a comprehensive ecological enterprise integrating intelligent manufacturing, energy conservation and environmental protection, science and technology finance, science and innovation cultural tourism and other diversified sectors. At present, the group holds and shares 52 enterprises, which is one of the top 100 enterprises in Qingdao City and one of the top 100 private series and one of the top 50 service industries in Shandong Province.

With “smart manufacturing + industrial chain” as the core, the company has been deeply engaged for nearly 30 years, cooperating with international first-class enterprises such as Shougang and Panzhihua, and providing high-quality products and service solutions for global high-end brands such as Haier, Hisense, SAIC-GM-Wuling, Geely Automobile, Jimei Group and Wanhua Group. At the same time, integrate the advantages of industrial development, invest in artificial intelligence, military intelligent manufacturing, science and technology education, green agriculture, new cultural tourism, new energy, new materials and other new quality productivity and strategic emerging industries, and strive to become an international first-class industrial development platform.

Keeping up with the national development strategy, they initiated and operated the “internationalization, ecological and intelligent” artificial intelligence manufacturing headquarters Base project led by Jinniu District, Chengdu, which integrates intelligent technology, cutting-edge science and innovation, smart office, modern business and other functions. The total land area of the project is about 175,334 sqm, and the first phase of the project is 52,667 sqm. Featuring intelligent transportation and assisted by the industrial Internet, five centers including AI+ industry center, industrial finance center, scientific and technological achievements transformation center, modern service center and global settlement center will be built, smart park platform and science and technology service system will be built, and multi-platform service mode of “main body + platform + science and technology service” will be built. We are committed to becoming the leader of the international first-class industrial platform.

After nearly 30 years of deep cultivation, the Group’s industrial strategic layout has formed a development pattern of “one body and two wings”. In the face of the new round of global scientific and technological revolution and industrial transformation, the Group has implemented a diversified development strategy, from the main sector of steel industry to energy conservation and environmental protection, science and technology finance, science and technology cultural tourism and other emerging sectors, has established international cooperation with more than 10 countries such as the Czech Republic, the United Kingdom, New Zealand, Finland, the United States, Israel, Japan, and has two overseas companies.